Package sewage and wastewater treatment plant

Package Sewage Treatment Plants…

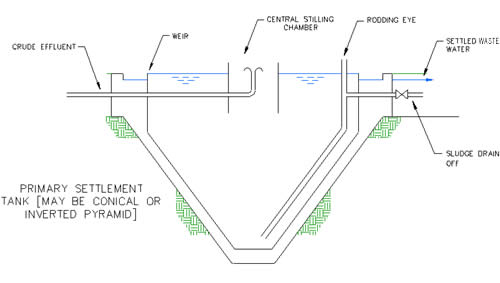

Sewage treatment plants are available in a modular or package form. The modern sewage treatment plant offers more efficient effluent management whilst providing effective wastewater treatment. Many plants will feature some form of preliminary treatment such as screening, grit or grease removal and primary sedimentation in advance of the biological treatment process.

After this there are a number of ways of providing secondary treatment. There follows a brief summary of the main types of plant available. The first few are aerobic fixed-film systems;

Biological Filter -- >>

The biological filter is used to treat either raw sewage that has been passed through a screen, or settled effluent from a primary tank.

Rotating Biological Contactors (RBCs) -- >>

The sewage is passed horizontally through a tank in which media discs are rotating; suspended on a horizontal shaft. About 40% of the surface area of each disc is being wetted at any one time. The sewage is absorbed into the biofilm on the disc and then gets aerated as the disc completes its cycle in the free air above the tank. This ensures that aerobic digestion can take place.

Power consumption is generally low and a 30:20 standard can be achieved.

Biological Aerated Filter (BAF) -- >>

These plants feature an aerated bed containing a submerged medium. Biofilm grows on the medium and cleans up the settled sewage. Any excess of biomass is removed by washing the bed.

Submerged Aerated Filter (SAF) -- >>

These plants are very similar to the biological aerated filter. They have a settling tank downstream which serves to retain and remove any excess biomass which is dislodged from the submerged medium. Oxygen is provided to aid the oxidation process through forced aeration.

There follows some of the activated sludge plants;

Extended Aeration -->>

These plants admit sewage and add some activated sludge, aerating the mixture for a suitable period of time. There are two types of unit; in the contact stabilisation plant the sewage solids are absorbed onto the activated sludge and then pass into a second chamber where digestion takes place. In the extended aeration plant the absorption and digestion take place in the same chamber.

In order to operate effectively these plants require the right combination of organic matter, activated sludge, air and contact time. The sludge and liquid are then separated by settlement, the liquor discharged and the sludge retained to be re-introduced to the incoming sewage stream. The retained sludge is aerated to assist the micro-organisms in their digestion of the sludge.

The plants do not smell and can generally achieve a 30:20 standard. They do require power and regular maintenance.

Sequencing Batch Reactor(SBR) - >>

Each reactor goes through a cycle of filling, aeration of the wastewater and the biomass, a settlement phase and drainage of the settled wastewater and removal of the excess of biomass.

Extended Biofiltration Plants

These are less common than activated sludge units. The raw sewage is re-circulated through a ventilated bed of plastic media on which the aerobic bacteria can be supported whilst they digest the organic matter in the sewage. These units produce less sludge than septic tanks or cesspools.

Odour can be a problem but the plants are tolerant of intermittent flows and are compact. A 30:20 standard can be achieved.

Choosing Your Plant…

Just like the local nursery there are plenty of plants to choose from. We can help you to select the right one for your needs, why not call us now

Sewerage Services

Sewerage Systems

Package Sewage and Wastewater Treatment Plant

Biological Filtration Secondary Treatment System

Rotating Biological Contactors

Biological Aerated Filter

Submerged Aerated Filters

The Treatment of Sewage using Activated Sludge

The Secondary Treatment of Sewage using a Sequencing Batch Reactor

Water Services >>